Mining operations carry inherent risks that demand more than standard safety protocols—they require deeply ingrained situational awareness and rapid response capabilities. Traditional training methods often fail to prepare workers for the complex, high-pressure scenarios they might face underground or in processing facilities. Immersive training solutions bridge this gap by creating realistic, repeatable experiences that build both knowledge and muscle memory. This approach doesn't just check compliance boxes—it fundamentally changes how workers perceive and react to hazards, reducing preventable incidents and their devastating human and financial costs.

When safety training becomes a bureaucratic exercise rather than a life-saving practice, operations pay the price in multiple currencies—human suffering, regulatory penalties, production losses, and reputational damage. The mining industry's historical incidents reveal patterns of overlooked warnings, improper hazard assessments, and emergency response failures—all issues that proper training could address. Modern operations cannot afford to repeat these mistakes when advanced training technologies offer superior alternatives to outdated classroom sessions.

Catastrophic mining accidents like the Pike River Mine explosion demonstrate how theoretical knowledge fails when untested in realistic conditions. Workers who only studied safety manuals couldn't respond effectively to rapidly changing underground situations. In contrast, immersive training creates neural pathways through repeated scenario practice, making correct responses instinctive during actual emergencies. This difference becomes particularly crucial for high-risk activities like operating heavy machinery or handling explosive materials where hesitation can prove fatal.

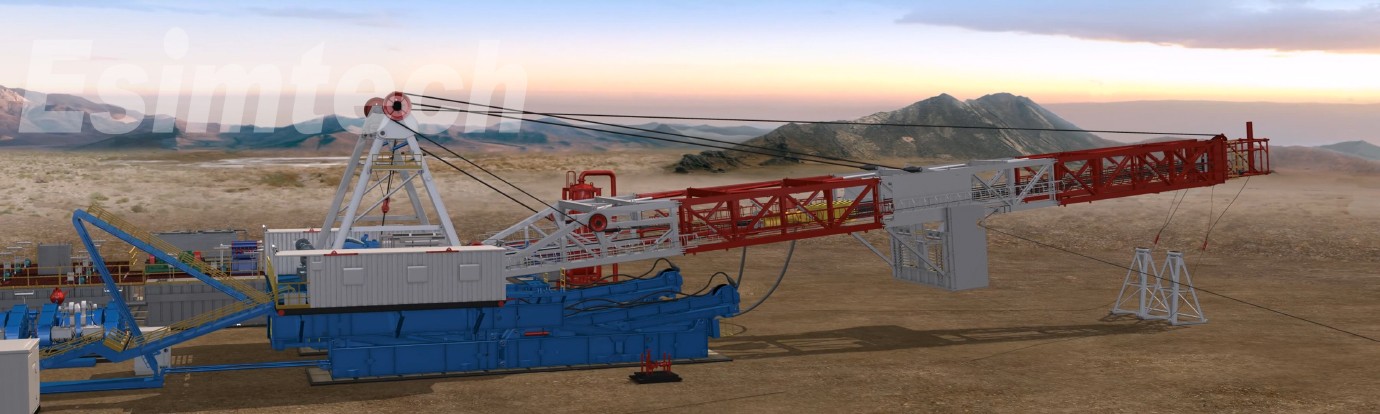

The financial implications of poor training extend far beyond regulatory fines. Unplanned shutdowns following accidents can cost millions per day in lost production, while equipment damage from improper operation creates unnecessary capital expenses. Insurance premiums rise with poor safety records, and recruitment becomes challenging when companies develop dangerous reputations. Investing in proper training solutions like Oil Rig Simulators for surface operations demonstrates a tangible commitment to worker safety that pays dividends across all business metrics.

Forward-thinking operations now measure training effectiveness not by hours logged but by demonstrated competency in simulated emergencies. This shift reflects the growing recognition that safety isn't about knowing procedures—it's about executing them flawlessly under stress. Companies leveraging Oil and Gas Simulation technologies report measurable decreases in incident rates and near-misses, proving the value of hands-on practice over passive learning.

Truly effective mining safety programs combine technological solutions with psychological principles to create lasting behavioral change. Virtual reality scenarios allow workers to experience hazardous situations without actual danger, building confidence along with knowledge. Motion-tracking systems analyze physical responses to ensure proper technique in equipment operation and emergency procedures, while biometric sensors monitor stress responses during simulated crises.

Scenario variability proves crucial—training must prepare workers for both common incidents and rare but catastrophic events. A proper Oil Rig Simulators system, for instance, would include not just standard drilling operations but also blowout scenarios, equipment failures, and extreme weather conditions. This breadth ensures workers develop adaptable problem-solving skills rather than rote responses to scripted situations. The most advanced systems even incorporate artificial intelligence to adjust scenario difficulty based on trainee performance.

Data analytics transform training from isolated events into continuous improvement cycles. Detailed performance metrics identify individual and team weaknesses for targeted remediation, while aggregated data reveals patterns that might indicate systemic safety issues. This approach aligns with modern safety management systems that view training as an ongoing process rather than periodic certification. When integrated with operational data, training systems can even predict which crews might need refreshers based on changing work conditions or equipment modifications.

| Training Component | Traditional Approach | Immersive Solution |

|---|---|---|

| Hazard Recognition | Photo identification in manuals | 360° virtual environments with dynamic hazards |

| Equipment Operation | Classroom diagrams and videos | Full-motion simulators with force feedback |

| Emergency Response | Written procedures and occasional drills | Stress-inoculation scenarios with biometric monitoring |

| Team Coordination | Theoretical communication protocols | Multi-user simulations with role-specific challenges |

Transitioning to immersive training requires careful planning to maximize adoption and return on investment. Successful implementations begin with pilot programs targeting high-risk activities or problem areas identified through incident reports. These controlled rollouts allow for system adjustments based on user feedback while building organizational confidence through visible success stories. Gradually expanding to broader applications creates momentum without overwhelming resources or personnel.

The most effective programs integrate training systems with existing safety management processes rather than treating them as standalone solutions. When Oil and Gas Simulation data feeds into risk assessment matrices and safety meeting agendas, it creates a closed-loop system where training directly informs operational improvements. This integration also helps justify continued investment by demonstrating concrete connections between training activities and measurable safety performance indicators.

Leadership engagement proves critical—when executives and site managers actively participate in immersive training, it signals organizational commitment while giving decision-makers firsthand experience with the technology's value. This top-down endorsement combined with bottom-up feedback from frontline workers creates the cultural shift needed to move beyond compliance-based safety toward genuine operational excellence.

Sustainability comes from designing programs that remain relevant as operations evolve. Modular training systems allow quick updates when introducing new equipment or processes, while cloud-based platforms ensure consistent standards across multiple sites. Regular content reviews with subject matter experts keep scenarios aligned with actual workplace conditions, preventing the training-reality gap that undermines many safety programs. The ultimate measure of success comes when workers themselves request additional training opportunities—a sign that safety has become an authentic cultural value rather than an imposed requirement.